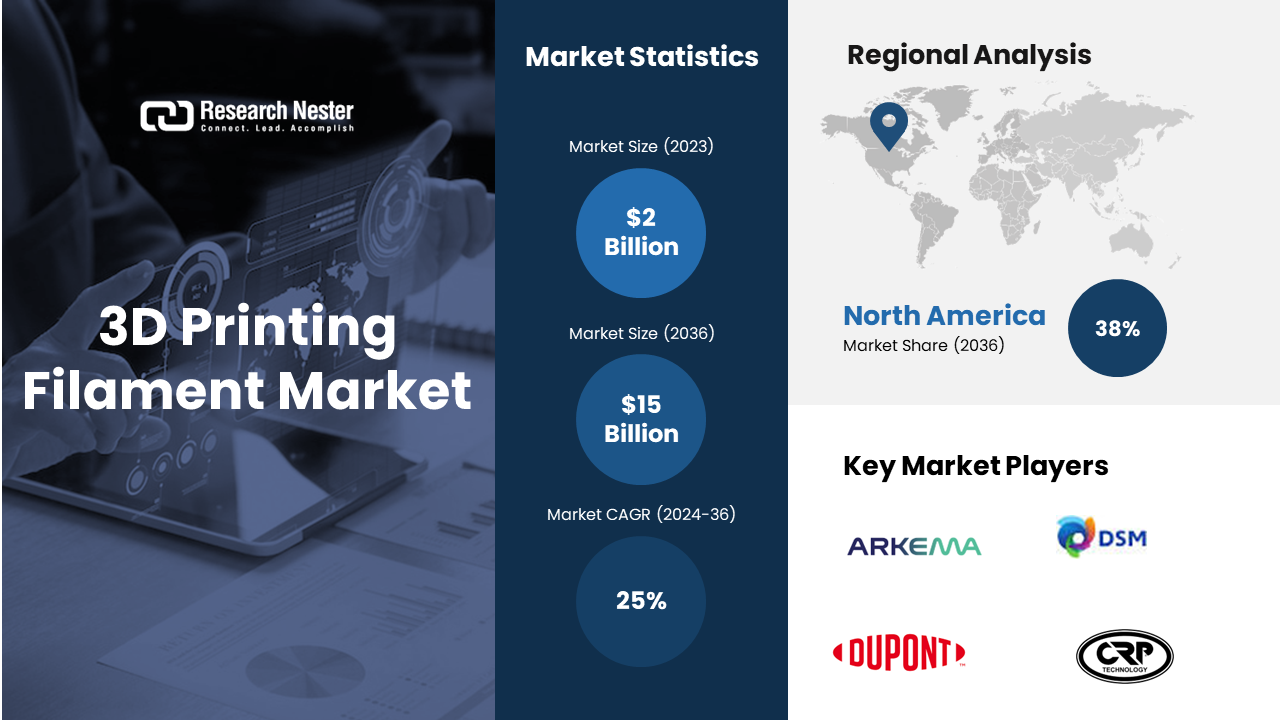

New York, Feb. 29, 2024 (GLOBE NEWSWIRE) -- The global 3D printing filament market size is slated to expand at ~25% CAGR between 2024 and 2036. The market is poised to garner a revenue of USD 15 billion by the end of 2036, up from a revenue of ~USD 2 billion in the year 2023.The growing worldwide automobile production is driving the market growth owing to the rising demand for personal vehicles, technology breakthroughs, and integration of artificial intelligence (AI), machine learning, and automation. The automobile parts made out[MK1] of 3D printing weigh 38% less compared to other materials and are stronger.

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-3504

In addition, the enhancing developments in 3D printing technology are fueling the market growth in the coming years. The incorporation of virtual and augmented reality in the 3D printing technology to give a visual experience to the users is expected to propel the market trends in the coming years. Laser direct structuring is applied in the manufacturing of more than[MK2] 100s of millions of devices every year, among which over 70% of them are antennas.

Fostering Metal 3D Printing for Various Purposes and Health Issues Across the Globe is Reinforcing the Growth of the 3D Printing Filament Market

The market growth in the coming years is analyzed to rise with the incidence of multiple orthopedic issues among the world population. The use of artificial intelligence and 3D technology printing in the orthopedic sector made treatments easy, non-invasive, and precise. The increasing application of 3D printing technology in making metal parts for aircraft is shooting up the market growth. NASA had tested the rocket engine parts with a California-based company[MK3] , Aerojet Rocketdyne that utilizes metal 3D printing methods for manufacturing.

3D Printing Filament Market: Regional Overview

Increasing Spending in the Aerospace & Defense Sector is Strengthening the Market Growth in the North American region

The 3D printing filament market of the North American region is anticipated to register a revenue share of 38% by the end of 2036 owing to the increasing expenditure in the aerospace & defense sector. The market growth is determined to rise as a result of the escalating global demand for defense and security along with the rise of travelers across the region. Multiplying spending on aircraft and military businesses in research and development and engineering is amplifying the market size. Boeing started applying 3D printing for the production of Wideband[MK4] Global SATCOM satellite for the U.S. Space Force on account of a deal worth USD 605 million.

Make an Inquiry Before Buying this Report @ https://www.researchnester.com/inquiries-before-buying-3504

Mounting Production of Electronics and Adoption of Technology is Aggregating the Market Expansion in the Asia Pacific Region

The Asia Pacific region 3D printing filament market is outlined to garner the second-largest revenue share in the coming years. The soaring electronics production followed by the integration of technology, affordability, and sustainability is promoting the market size. Nearly 14% of the 3D international patent families are acquired by Japan followed by China and South Korea with 4% and 3% respectively as of 2023[MK5] .

3D Printing Filament, Segmentation by Type

- Plastics

- Metals

- Ceramics

The plastics segment is anticipated to secure a significant market share of 54% in the coming years owing to the increasing demand for thermoplastics across the world. The use of thermoplastics is increasing day by day on account of their lightweight, and environmentally sustainable nature. The use of additive manufacturing processes in the aircraft[MK6] helps to decrease the weight by nearly 50%. Which reduces the fuel cost by 5.5% as of 2022 reports. The increasing use in the end-user sectors such as aerospace, automotive, electrical, construction, and electronics sectors is fueling the market segment size.

3D Printing Filament, Segmentation by End-User

- Aerospace & Defense

- Medical

- Automotive

- Electronics

The aerospace & defense segment in market is projected to register a noteworthy revenue share by the end of 2036. The growth of the market segment is attributed to the enhanced usage of additive manufacturing methods to develop parts for jet engine models, drone housing, and other defense and aerospace spare parts. Further, 3D technology is highly applied in the aerospace sector to test and prototype new ideas by creating end-use parts and tools in the aircraft interiors, jigs for maintenance, designs, and jet engines. The new jet Boeing 777x has more than 280 printed parts making it the world's best efficient[MK7] twin jet with a fuel reduction of over 10% and operation cost of over 8%.

A few of the well-known industry leaders in the 3D printing filament market that are profiled by Research Nester are BASF 3D Printing Solutions GmbH, Saudi Basic Industries Corporation, Arkema SA, DuPont de Nemours, Inc., Oxford Performance Materials, Inc., MG Chemicals, Shenzhen Esun Industrial CO., Ltd., CRP Technology S.r.l., Koninklijke DSM N.V., Materialise NV, Raise 3D, and others.

Recent Development in the Market

- Raise 3D declared the introduction of a metal 3D printing solution along with BASF. The new addition features Ultrafuse 316L and 17-4 PH metal filaments facilitating the high-speed and less expensive 3D printing of metal parts.

- Saudi Basic Industries Corporation launched a novel, flame-retardant 3D printing material compliant with the global fire-safety regulations of the rail industry. The new product is used for the production and repair of rail parts, along with on-demand printing of big, and complicated exterior and interior parts in less quantity.

Read our insightful Blogs and Data-driven Case Studies:

- Hydrogen - The Fuel of the Future

This blog uncovers the future of fuel industry featuring hydrogen. Our guide discusses about application, color spectrum and production of hydrogen. Also, it provides regional scope of hydrogen.

https://www.researchnester.com/blog/chemicals/advanced-materials/Hydrogen-fuel-of-the-future

- A Specialty Chemical Firm to open up New Channels for the Large-scale Production of Petrochemicals to fulfill market needs

The case study shows how a specialty chemical firm fulfills market needs. After extensive market analysis, company launched technically distinct goods, which further facilitated successfull business expansion.

About Research Nester

Research Nester is a one-stop service provider with a client base in more than 50 countries, leading in strategic market research and consulting with an unbiased and unparalleled approach to helping global industrial players, conglomerates, and executives for their future investments while avoiding forthcoming uncertainties. With an out-of-the-box mindset to produce statistical and analytical market research reports, we provide strategic consulting so that our clients can make wise business decisions with clarity while strategizing and planning for their forthcoming needs and succeed in achieving their future endeavors. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds.