MONTRÉAL, Dec. 03, 2024 (GLOBE NEWSWIRE) -- Cerro de Pasco Resources Inc. (CSE: CDPR) (OTCQB: GPPRF) (FRA: N8HP) (“CDPR” or the “Company”) is pleased to report that the 40-hole drill program at its Quiulacocha Tailings Project (“TSF Project”) in Central Peru has been successfully completed, providing more than 1,000 samples of which 177 have been assayed to date, including the SPT04 drillhole released on October 15.

Key Highlights

- 177 assay samples from nine drill holes, equivalent to 15% of the current drill program, indicate an average silver grade of 1.72 ounces per tonne (oz/t) of silver (53.64 g/t Ag), 37% higher than the average of shallow auger samples reported by Brophy (2012) in the north and central sections of the TSF.

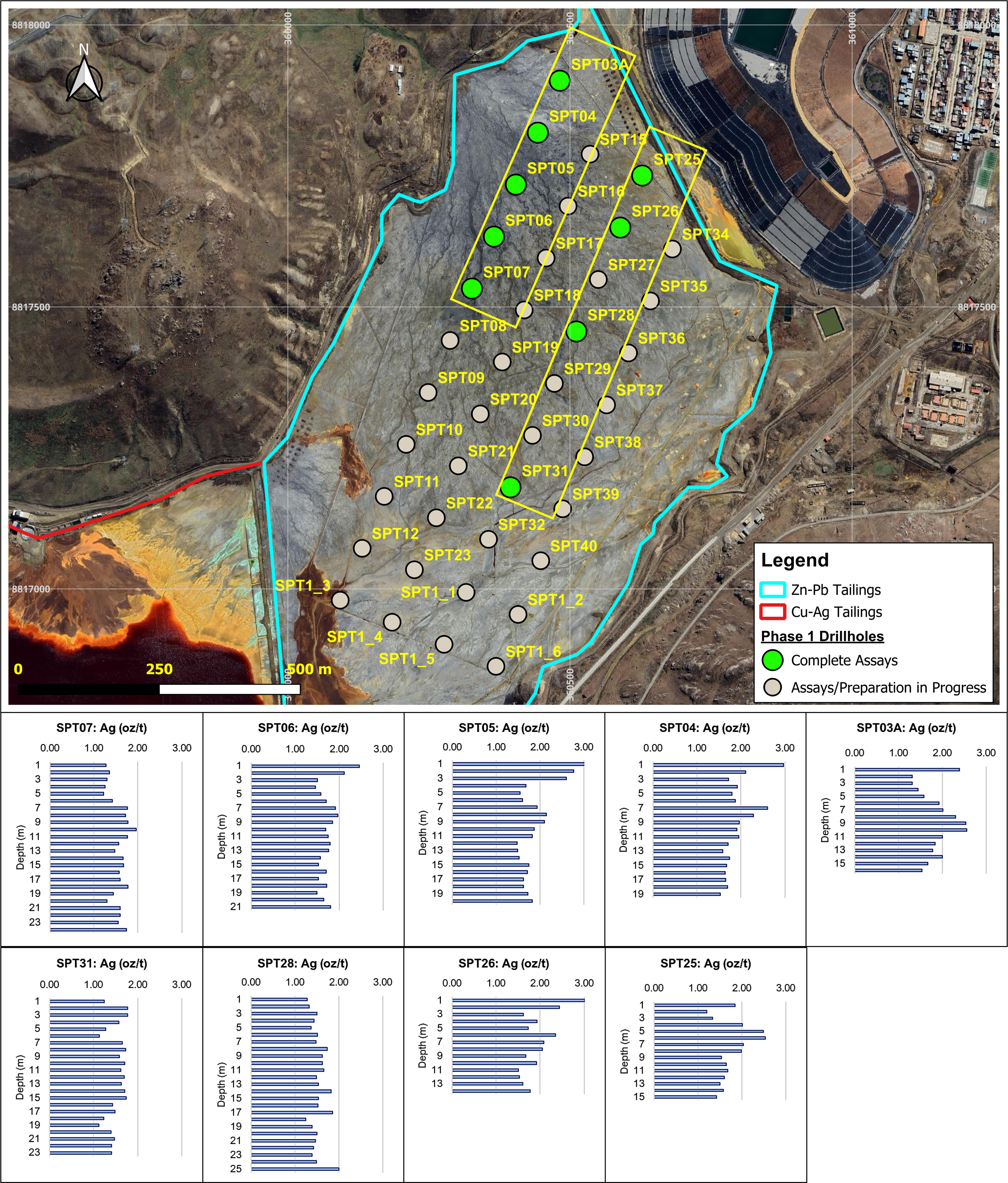

- Results indicate that the metal content is consistent at depth and laterally across 400 and 600 meters of the drilled area assayed to date (Figure 2).

- Gallium, a critical mineral used in high-performance microchips for advanced military technologies, is present with an average grade of 34.61 g/t in these 177 samples, reaching a maximum of 144 g/t, increasing towards the center of the TSF.

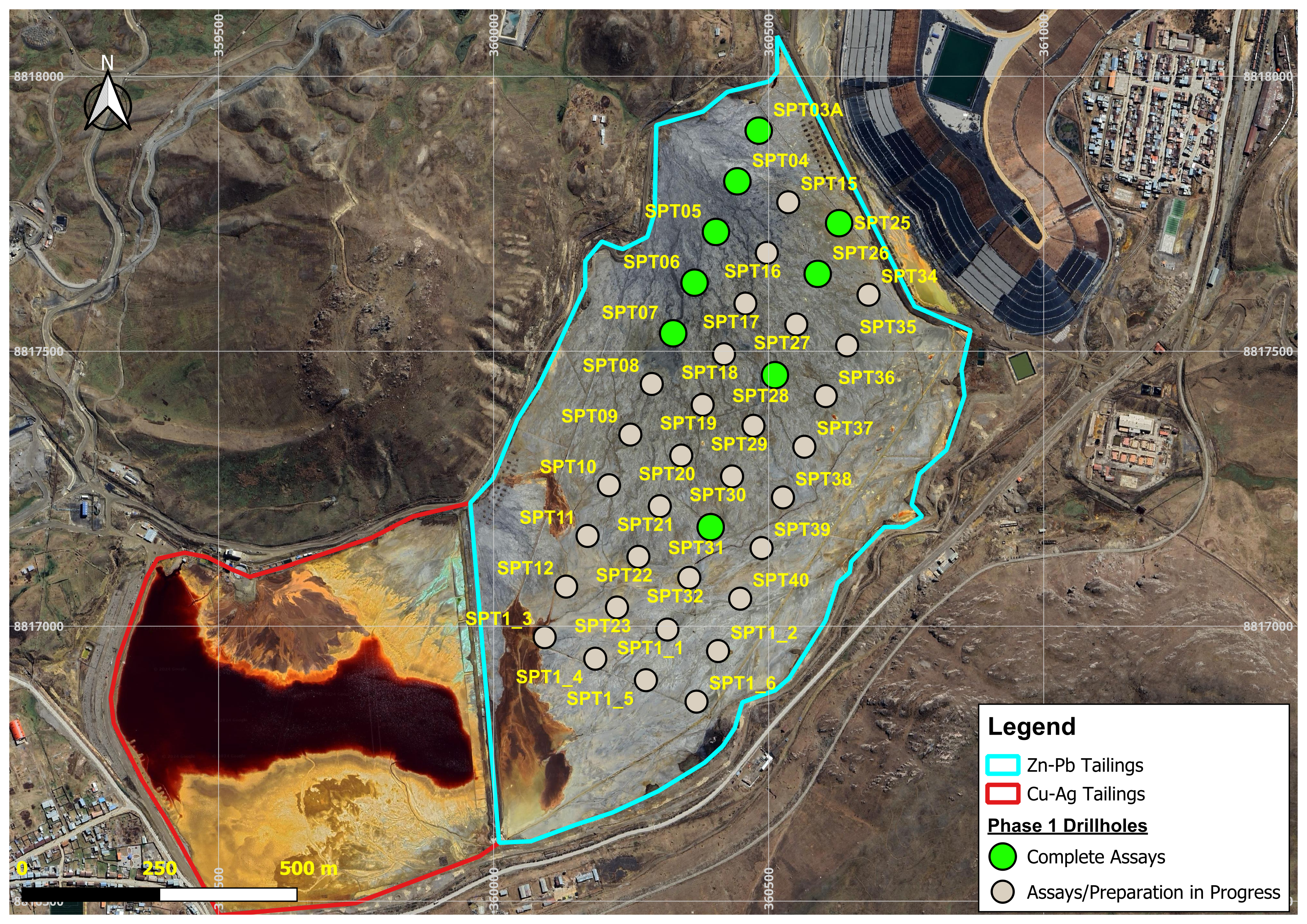

Figure 1: 40-hole Quiulacocha Drill Program showing drillholes with completed assays

CDPR's CEO, Guy Goulet commented:

"These results are highly encouraging and exceed our initial projections, particularly regarding silver continuity and grade. In addition to zinc, lead, silver, copper, and gold, the detection of elements like gallium and indium—critical for advanced 5G technologies, robotics, and nuclear medicine—presents the potential for valuable by-product metal credits in the planned concentrates.

Representative composite samples will now undergo metallurgical testing to support further studies. These findings will inform our planning for an extended drilling campaign, set to commence in the second quarter of 2025, focusing on the remaining tailings."

Assay Results

Inspectorate Services Perú S.A.C., a Peruvian subsidiary of Bureau Veritas, released the assay results of 177 samples from nine drillholes, including the SPT04 drillhole released on October 15, distributed across the northern and central areas of the polymetallic tailings (Ag-Zn-Pb; Figure 1). These assays, equivalent to 15% of the current drilling program, show average grades of 1.72 oz/t Ag (53.64 g/t Ag), 1.56% Zn, and 0.77% Pb (Table 1).

The results from each drillhole show that the metal content is continuous at depth. The plots covering 400 and 600 meters across the drilled area, show the lateral continuity of Ag, Zn, and Pb grades (Figure 2). The predominant silver grades are in the range of 1.40 to 1.80 oz/t, with slightly higher grades occurring in the northeastern portion of the drilling area, closer to the Excelsior stockpile.

These assay results are derived from a combination of multi-element ICP (detecting 60 elements), Atomic Absorption (for determining upper limits of metals Zn, Pb, and Cu), and Fire Assay for Au. The assay results for each of the nine drillholes are presented in Table 2 to Table 10.

The Iron results also indicate consistent presence of pyrite throughout the deposit. Pyrite (indicatively 50% of the tailings) may represent a valuable by-product for the project. The upcoming metallurgical test work program will also evaluate the potential for pyrite recovery, including likely grades, by-products and impurities.

Figure 2: Silver grade across 400 meters of the Quiulacocha tailings

Table 1. Statistical summary of assay results from 177 samples, nine drillholes

| Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe | |

| Mean | 1.72 | 53.64 | 1.56 | 0.77 | 0.07 | 0.07 | 34.61 | 18.37 | 29.78 |

| Median | 1.66 | 51.66 | 1.54 | 0.66 | 0.06 | 0.04 | 28.27 | 19.14 | 29.15 |

| St. Dev | 0.36 | 11.11 | 0.56 | 0.35 | 0.05 | 0.09 | 22.05 | 4.21 | 3.24 |

| Minimum | 1.12 | 34.88 | 0.25 | 0.36 | 0.01 | 0.01 | 0.00 | 2.32 | 19.02 |

| Maximum | 3.29 | 102.36 | 3.57 | 2.25 | 0.27 | 0.57 | 144.00 | 28.08 | 37.74 |

| Samples | 177 | 177 | 177 | 177 | 177 | 177 | 177 | 177 | 177 |

Table 2. Assay results, Drillhole SPT03A

| Drillhole: SPT03A | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 2.39 | 74.34 | 0.38 | 0.69 | 0.02 | 0.08 | 31.67 | 8.16 | 31.83 |

| 1 | 2 | 1.31 | 40.75 | 1.25 | 0.48 | 0.03 | 0.03 | 22.56 | 16.45 | 29.15 |

| 2 | 3 | 1.31 | 40.75 | 1.15 | 0.44 | 0.03 | 0.03 | 26.19 | 14.42 | 29.91 |

| 3 | 4 | 1.45 | 45.10 | 0.92 | 0.38 | 0.02 | 0.02 | 19.26 | 13.12 | 31.85 |

| 4 | 5 | 1.58 | 49.14 | 1.18 | 0.44 | 0.03 | 0.02 | 23.37 | 14.63 | 31.74 |

| 5 | 6 | 1.92 | 59.72 | 2.07 | 0.76 | 0.05 | 0.03 | 32.61 | 19.59 | 31.64 |

| 6 | 7 | 2.01 | 62.52 | 2.62 | 0.97 | 0.04 | 0.03 | 22.30 | 20.59 | 29.97 |

| 7 | 8 | 2.30 | 71.54 | 3.01 | 1.24 | 0.05 | 0.05 | 15.09 | 18.34 | 34.26 |

| 8 | 9 | 2.53 | 78.69 | 3.57 | 1.21 | 0.07 | 0.03 | 15.03 | 21.05 | 34.63 |

| 9 | 10 | 2.56 | 79.62 | 3.51 | 1.29 | 0.08 | 0.04 | 15.17 | 24.56 | 36.00 |

| 10 | 11 | 2.00 | 62.21 | 2.45 | 0.83 | 0.06 | 0.04 | 17.94 | 23.38 | 34.10 |

| 11 | 12 | 1.84 | 57.23 | 1.68 | 0.63 | 0.06 | 0.05 | 13.24 | 16.33 | 34.27 |

| 12 | 13 | 1.78 | 55.36 | 1.39 | 0.53 | 0.05 | 0.03 | 19.92 | 14.62 | 32.25 |

| 13 | 14 | 2.00 | 62.21 | 1.90 | 0.65 | 0.05 | 0.04 | 17.06 | 16.07 | 32.46 |

| 14 | 15 | 1.67 | 51.94 | 1.31 | 0.58 | 0.06 | 0.01 | 20.68 | 13.94 | 31.52 |

| 15 | 16 | 1.53 | 47.59 | 1.20 | 0.73 | 0.08 | 0.05 | 28.91 | 16.14 | 26.58 |

| Mean | 1.89 | 58.67 | 1.85 | 0.74 | 0.05 | 0.04 | 21.31 | 16.96 | 32.01 | |

Table 3. Assay results, Drillhole SPT04

| Drillhole: SPT04 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 2.97 | 92.38 | 0.34 | 1.37 | 0.02 | 0.08 | 72.95 | 23.28 | 22.59 |

| 1 | 2 | 2.11 | 65.63 | 1.13 | 0.69 | 0.03 | 0.04 | 25.33 | 19.71 | 33.41 |

| 2 | 3 | 1.72 | 53.50 | 1.57 | 0.54 | 0.02 | 0.02 | 9.79 | 20.23 | 35.23 |

| 3 | 4 | 1.92 | 59.72 | 2.29 | 0.59 | 0.03 | 0.03 | 19.54 | 20.55 | 36.75 |

| 4 | 5 | 1.80 | 55.99 | 1.97 | 0.54 | 0.03 | 0.02 | 19.55 | 18.80 | 36.36 |

| 5 | 6 | 1.87 | 58.16 | 1.83 | 0.58 | 0.04 | 0.03 | 21.76 | 19.21 | 35.02 |

| 6 | 7 | 2.61 | 81.18 | 2.44 | 0.91 | 0.05 | 0.03 | 17.18 | 22.53 | 34.71 |

| 7 | 8 | 2.28 | 70.92 | 2.58 | 0.79 | 0.05 | 0.04 | 19.53 | 20.55 | 34.32 |

| 8 | 9 | 1.96 | 60.96 | 2.98 | 0.78 | 0.06 | 0.03 | 15.76 | 20.81 | 37.74 |

| 9 | 10 | 1.91 | 59.41 | 2.39 | 0.59 | 0.05 | 0.04 | 12.64 | 16.06 | 35.32 |

| 10 | 11 | 1.95 | 60.65 | 2.60 | 0.69 | 0.06 | 0.04 | 15.71 | 18.48 | 34.19 |

| 11 | 12 | 1.71 | 53.19 | 1.58 | 0.73 | 0.06 | 0.05 | 27.85 | 16.28 | 33.02 |

| 12 | 13 | 1.59 | 49.45 | 1.44 | 0.69 | 0.06 | 0.05 | 27.17 | 13.48 | 29.81 |

| 13 | 14 | 1.74 | 54.12 | 1.37 | 1.18 | 0.09 | 0.06 | 50.23 | 20.46 | 31.62 |

| 14 | 15 | 1.68 | 52.25 | 1.60 | 0.97 | 0.09 | 0.08 | 41.54 | 18.65 | 32.57 |

| 15 | 16 | 1.64 | 51.01 | 1.58 | 0.81 | 0.11 | 0.12 | 30.66 | 18.41 | 32.93 |

| 16 | 17 | 1.65 | 51.32 | 1.68 | 0.69 | 0.18 | 0.21 | 22.97 | 16.75 | 31.78 |

| 17 | 18 | 1.70 | 52.88 | 1.46 | 0.89 | 0.27 | 0.22 | 0.00 | 9.12 | 20.60 |

| 18 | 19 | 1.53 | 47.59 | 1.34 | 0.64 | 0.12 | 0.11 | 30.83 | 15.30 | 28.06 |

| Mean | 1.91 | 59.49 | 1.80 | 0.77 | 0.07 | 0.07 | 25.32 | 18.35 | 32.42 | |

Table 4. Assay results, Drillhole SPT05

| Drillhole: SPT05 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 3.29 | 102.33 | 0.33 | 1.37 | 0.01 | 0.09 | 48.24 | 5.50 | 19.85 |

| 1 | 2 | 2.77 | 86.16 | 0.62 | 0.88 | 0.01 | 0.06 | 28.76 | 9.82 | 27.02 |

| 2 | 3 | 2.60 | 80.87 | 0.86 | 0.86 | 0.01 | 0.06 | 34.33 | 15.62 | 27.86 |

| 3 | 4 | 1.68 | 52.25 | 1.50 | 0.45 | 0.02 | 0.03 | 18.84 | 15.87 | 33.21 |

| 4 | 5 | 1.55 | 48.21 | 1.49 | 0.42 | 0.02 | 0.03 | 15.49 | 15.14 | 33.38 |

| 5 | 6 | 1.60 | 49.77 | 1.50 | 0.45 | 0.02 | 0.02 | 20.16 | 14.55 | 32.21 |

| 6 | 7 | 1.94 | 60.34 | 1.90 | 0.54 | 0.05 | 0.03 | 16.43 | 18.05 | 32.28 |

| 7 | 8 | 2.15 | 66.87 | 2.31 | 0.63 | 0.06 | 0.04 | 20.09 | 21.14 | 32.47 |

| 8 | 9 | 2.10 | 65.32 | 2.17 | 0.63 | 0.05 | 0.03 | 15.97 | 20.15 | 32.35 |

| 9 | 10 | 1.87 | 58.16 | 2.32 | 0.59 | 0.05 | 0.03 | 13.24 | 19.51 | 32.40 |

| 10 | 11 | 1.83 | 56.92 | 2.09 | 0.62 | 0.06 | 0.04 | 13.83 | 17.62 | 31.59 |

| 11 | 12 | 1.48 | 46.03 | 1.47 | 0.51 | 0.05 | 0.04 | 12.06 | 15.09 | 31.31 |

| 12 | 13 | 1.49 | 46.34 | 1.42 | 0.85 | 0.09 | 0.04 | 31.56 | 18.43 | 30.72 |

| 13 | 14 | 1.53 | 47.59 | 1.19 | 0.67 | 0.07 | 0.05 | 25.05 | 15.08 | 32.08 |

| 14 | 15 | 1.75 | 54.43 | 1.55 | 1.75 | 0.11 | 0.07 | 60.47 | 26.44 | 28.94 |

| 15 | 16 | 1.71 | 53.19 | 2.30 | 1.53 | 0.13 | 0.16 | 48.62 | 24.68 | 29.25 |

| 16 | 17 | 1.63 | 50.70 | 1.80 | 0.73 | 0.12 | 0.14 | 19.96 | 17.99 | 32.15 |

| 17 | 18 | 1.63 | 50.70 | 1.95 | 0.71 | 0.14 | 0.17 | 13.66 | 20.21 | 31.83 |

| 18 | 19 | 1.73 | 53.81 | 1.76 | 0.51 | 0.22 | 0.29 | 22.08 | 17.65 | 29.53 |

| 19 | 20 | 1.82 | 56.61 | 1.53 | 0.43 | 0.27 | 0.45 | 23.80 | 15.64 | 27.95 |

| Mean | 1.91 | 59.33 | 1.60 | 0.76 | 0.08 | 0.09 | 25.13 | 17.21 | 30.42 | |

Table 5. Assay results, Drillhole SPT06

| Drillhole: SPT06 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 2.46 | 76.51 | 0.36 | 1.00 | 0.02 | 0.07 | 36.46 | 13.26 | 26.86 |

| 1 | 2 | 2.11 | 65.63 | 0.31 | 0.99 | 0.02 | 0.06 | 39.02 | 19.16 | 26.79 |

| 2 | 3 | 1.51 | 46.97 | 1.13 | 0.51 | 0.02 | 0.04 | 22.26 | 19.81 | 28.17 |

| 3 | 4 | 1.46 | 45.41 | 1.29 | 0.44 | 0.02 | 0.03 | 19.57 | 17.34 | 32.50 |

| 4 | 5 | 1.58 | 49.14 | 1.17 | 0.47 | 0.02 | 0.03 | 24.78 | 16.82 | 29.33 |

| 5 | 6 | 1.71 | 53.19 | 1.08 | 0.57 | 0.04 | 0.03 | 22.89 | 17.78 | 28.41 |

| 6 | 7 | 1.92 | 59.72 | 1.55 | 0.60 | 0.05 | 0.03 | 28.94 | 19.45 | 32.86 |

| 7 | 8 | 1.97 | 61.27 | 1.75 | 0.57 | 0.05 | 0.03 | 25.24 | 19.18 | 32.50 |

| 8 | 9 | 1.85 | 57.54 | 1.61 | 0.57 | 0.05 | 0.03 | 24.70 | 18.91 | 29.17 |

| 9 | 10 | 1.69 | 52.56 | 1.57 | 0.57 | 0.05 | 0.03 | 24.28 | 17.43 | 29.42 |

| 10 | 11 | 1.75 | 54.43 | 1.80 | 0.60 | 0.05 | 0.03 | 13.94 | 17.68 | 28.11 |

| 11 | 12 | 1.80 | 55.99 | 1.93 | 0.57 | 0.05 | 0.04 | 13.36 | 17.66 | 27.51 |

| 12 | 13 | 1.76 | 54.74 | 1.56 | 1.75 | 0.12 | 0.05 | 71.19 | 8.20 | 26.16 |

| 13 | 14 | 1.57 | 48.83 | 1.48 | 0.72 | 0.06 | 0.04 | 28.77 | 16.68 | 27.74 |

| 14 | 15 | 1.53 | 47.59 | 1.73 | 0.99 | 0.07 | 0.08 | 39.61 | 20.48 | 29.48 |

| 15 | 16 | 1.71 | 53.19 | 1.83 | 1.60 | 0.12 | 0.09 | 60.65 | 8.52 | 26.85 |

| 16 | 17 | 1.53 | 47.59 | 1.58 | 0.84 | 0.10 | 0.13 | 34.78 | 22.76 | 27.89 |

| 17 | 18 | 1.72 | 53.50 | 2.10 | 0.84 | 0.14 | 0.15 | 32.68 | 21.63 | 29.41 |

| 18 | 19 | 1.50 | 46.66 | 1.74 | 0.51 | 0.20 | 0.34 | 19.61 | 17.56 | 26.54 |

| 19 | 20 | 1.65 | 51.32 | 1.67 | 0.49 | 0.23 | 0.39 | 19.75 | 16.01 | 27.33 |

| 20 | 21 | 1.81 | 56.30 | 1.91 | 0.51 | 0.23 | 0.32 | 18.75 | 17.46 | 27.62 |

| Mean | 1.74 | 54.19 | 1.48 | 0.75 | 0.08 | 0.10 | 29.58 | 17.32 | 28.60 | |

Table 6. Assay results, Drillhole SPT07

| Drillhole: SPT07 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 1.28 | 39.81 | 1.17 | 0.59 | 0.03 | 0.04 | 26.71 | 17.62 | 28.02 |

| 1 | 2 | 1.36 | 42.30 | 1.49 | 0.68 | 0.03 | 0.04 | 38.85 | 18.89 | 28.54 |

| 2 | 3 | 1.30 | 40.43 | 1.08 | 0.47 | 0.02 | 0.03 | 23.98 | 17.45 | 28.73 |

| 3 | 4 | 1.26 | 39.19 | 0.92 | 0.44 | 0.02 | 0.03 | 29.57 | 17.67 | 28.11 |

| 4 | 5 | 1.22 | 37.95 | 0.97 | 0.40 | 0.02 | 0.03 | 25.49 | 16.10 | 29.66 |

| 5 | 6 | 1.42 | 44.17 | 1.08 | 0.45 | 0.03 | 0.04 | 26.29 | 17.68 | 32.52 |

| 6 | 7 | 1.76 | 54.74 | 1.14 | 0.50 | 0.03 | 0.03 | 27.38 | 15.84 | 33.28 |

| 7 | 8 | 1.72 | 53.50 | 1.13 | 0.62 | 0.05 | 0.03 | 42.97 | 19.81 | 28.64 |

| 8 | 9 | 1.77 | 55.05 | 1.45 | 0.70 | 0.06 | 0.03 | 40.32 | 21.04 | 27.80 |

| 9 | 10 | 1.96 | 60.96 | 1.72 | 0.60 | 0.06 | 0.04 | 30.32 | 21.89 | 29.33 |

| 10 | 11 | 1.76 | 54.74 | 1.46 | 0.61 | 0.06 | 0.03 | 31.08 | 17.84 | 28.56 |

| 11 | 12 | 1.57 | 48.83 | 1.27 | 0.52 | 0.04 | 0.04 | 28.27 | 17.32 | 28.23 |

| 12 | 13 | 1.48 | 46.03 | 1.37 | 0.81 | 0.08 | 0.03 | 36.12 | 21.39 | 27.34 |

| 13 | 14 | 1.66 | 51.63 | 1.50 | 0.75 | 0.07 | 0.04 | 31.92 | 18.11 | 28.98 |

| 14 | 15 | 1.68 | 52.25 | 1.58 | 0.55 | 0.05 | 0.03 | 20.08 | 17.29 | 29.28 |

| 15 | 16 | 1.58 | 49.14 | 1.14 | 1.23 | 0.08 | 0.07 | 40.45 | 21.06 | 27.14 |

| 16 | 17 | 1.60 | 49.77 | 1.35 | 0.97 | 0.08 | 0.06 | 39.23 | 20.57 | 27.84 |

| 17 | 18 | 1.77 | 55.05 | 1.63 | 1.41 | 0.11 | 0.08 | 44.90 | 23.47 | 27.59 |

| 18 | 19 | 1.44 | 44.79 | 2.02 | 0.79 | 0.08 | 0.12 | 26.67 | 20.79 | 28.66 |

| 19 | 20 | 1.30 | 40.43 | 1.55 | 0.57 | 0.10 | 0.15 | 21.08 | 16.21 | 26.03 |

| 20 | 21 | 1.60 | 49.77 | 2.16 | 0.56 | 0.20 | 0.20 | 22.85 | 21.20 | 26.82 |

| 21 | 22 | 1.60 | 49.77 | 1.94 | 0.49 | 0.22 | 0.34 | 22.43 | 19.18 | 26.34 |

| 22 | 23 | 1.55 | 48.21 | 1.45 | 0.75 | 0.07 | 0.05 | 30.16 | 19.33 | 27.99 |

| 23 | 24 | 1.74 | 54.12 | 2.25 | 0.58 | 0.22 | 0.24 | 19.99 | 21.17 | 28.52 |

| Mean | 1.56 | 48.44 | 1.45 | 0.67 | 0.08 | 0.08 | 30.30 | 19.12 | 28.50 | |

Table 7. Assay results, Drillhole SPT25

| Drillhole: SPT25 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 1.85 | 57.54 | 0.31 | 1.06 | 0.03 | 0.06 | 78.08 | 22.70 | 23.25 |

| 1 | 2 | 1.20 | 37.32 | 0.99 | 0.79 | 0.03 | 0.04 | 60.31 | 21.16 | 28.69 |

| 2 | 3 | 1.33 | 41.37 | 0.95 | 0.50 | 0.02 | 0.04 | 38.35 | 19.85 | 31.48 |

| 3 | 4 | 2.01 | 62.52 | 1.94 | 0.68 | 0.03 | 0.03 | 12.77 | 21.65 | 31.39 |

| 4 | 5 | 2.49 | 77.45 | 2.42 | 0.82 | 0.04 | 0.04 | 17.64 | 20.87 | 33.84 |

| 5 | 6 | 2.53 | 78.69 | 2.52 | 0.80 | 0.04 | 0.05 | 19.57 | 20.45 | 35.06 |

| 6 | 7 | 2.03 | 63.14 | 2.71 | 0.77 | 0.04 | 0.03 | 19.20 | 20.10 | 33.95 |

| 7 | 8 | 1.99 | 61.90 | 2.68 | 0.68 | 0.05 | 0.03 | 19.09 | 19.61 | 35.13 |

| 8 | 9 | 1.54 | 47.90 | 1.74 | 0.62 | 0.06 | 0.04 | 23.60 | 15.65 | 28.91 |

| 9 | 10 | 1.65 | 51.32 | 1.89 | 0.56 | 0.06 | 0.03 | 19.44 | 14.91 | 31.74 |

| 10 | 11 | 1.68 | 52.25 | 1.78 | 0.66 | 0.06 | 0.03 | 24.28 | 16.26 | 32.19 |

| 11 | 12 | 1.60 | 49.77 | 1.54 | 0.65 | 0.06 | 0.04 | 18.69 | 15.65 | 32.93 |

| 12 | 13 | 1.50 | 46.66 | 1.53 | 0.92 | 0.07 | 0.07 | 35.53 | 17.56 | 32.18 |

| 13 | 14 | 1.58 | 49.14 | 1.66 | 0.84 | 0.08 | 0.09 | 32.13 | 15.91 | 34.51 |

| 14 | 15 | 1.42 | 44.17 | 1.32 | 0.71 | 0.08 | 0.08 | 28.22 | 16.54 | 31.73 |

| Mean | 1.76 | 54.74 | 1.73 | 0.74 | 0.05 | 0.05 | 29.79 | 18.59 | 31.80 | |

Table 8. Assay results, Drillhole SPT26

| Drillhole: SPT26 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 3.02 | 93.93 | 0.25 | 2.25 | 0.02 | 0.07 | 144.00 | 22.48 | 19.02 |

| 1 | 2 | 2.44 | 75.89 | 0.57 | 1.82 | 0.09 | 0.06 | 129.00 | 19.36 | 24.79 |

| 2 | 3 | 1.62 | 50.39 | 1.25 | 0.66 | 0.03 | 0.03 | 54.72 | 18.00 | 32.32 |

| 3 | 4 | 1.93 | 60.03 | 1.67 | 0.63 | 0.04 | 0.03 | 33.40 | 21.94 | 32.74 |

| 4 | 5 | 1.73 | 53.81 | 1.87 | 0.56 | 0.03 | 0.03 | 13.60 | 21.36 | 29.92 |

| 5 | 6 | 2.35 | 73.09 | 2.87 | 0.72 | 0.04 | 0.03 | 25.04 | 18.28 | 32.04 |

| 6 | 7 | 2.09 | 65.01 | 2.30 | 0.63 | 0.05 | 0.03 | 19.84 | 24.63 | 34.65 |

| 7 | 8 | 2.05 | 63.76 | 2.02 | 0.58 | 0.05 | 0.03 | 21.88 | 23.75 | 35.00 |

| 8 | 9 | 1.67 | 51.94 | 1.81 | 0.59 | 0.06 | 0.03 | 19.16 | 20.13 | 31.22 |

| 9 | 10 | 1.92 | 59.72 | 1.86 | 0.63 | 0.06 | 0.03 | 16.28 | 20.98 | 34.41 |

| 10 | 11 | 1.51 | 46.97 | 1.71 | 0.64 | 0.06 | 0.03 | 11.08 | 19.78 | 31.62 |

| 11 | 12 | 1.53 | 47.59 | 1.54 | 0.54 | 0.05 | 0.04 | 5.04 | 18.77 | 32.92 |

| 12 | 13 | 1.61 | 50.08 | 1.19 | 0.55 | 0.05 | 0.04 | 23.04 | 17.93 | 34.22 |

| 13 | 14 | 1.77 | 55.05 | 1.37 | 1.21 | 0.09 | 0.07 | 56.92 | 22.52 | 33.29 |

| Mean | 1.95 | 60.52 | 1.59 | 0.86 | 0.05 | 0.04 | 40.93 | 20.71 | 31.30 | |

Table 9. Assay results, Drillhole SPT28

| Drillhole: SPT28 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 1.28 | 39.81 | 0.96 | 0.51 | 0.03 | 0.03 | 39.18 | 18.66 | 29.31 |

| 1 | 2 | 1.33 | 41.37 | 1.35 | 0.85 | 0.03 | 0.03 | 50.47 | 23.47 | 26.86 |

| 2 | 3 | 1.50 | 46.66 | 1.42 | 1.32 | 0.03 | 0.17 | 67.11 | 23.83 | 26.22 |

| 3 | 4 | 1.44 | 44.79 | 0.88 | 0.57 | 0.03 | 0.03 | 44.62 | 20.24 | 29.13 |

| 4 | 5 | 1.37 | 42.61 | 0.91 | 0.53 | 0.03 | 0.03 | 42.72 | 18.92 | 28.83 |

| 5 | 6 | 1.51 | 46.97 | 1.36 | 0.56 | 0.04 | 0.03 | 36.79 | 19.68 | 32.13 |

| 6 | 7 | 1.48 | 46.03 | 1.27 | 0.51 | 0.03 | 0.03 | 34.36 | 18.33 | 28.78 |

| 7 | 8 | 1.74 | 54.12 | 1.58 | 0.55 | 0.05 | 0.04 | 39.51 | 19.14 | 28.80 |

| 8 | 9 | 1.62 | 50.39 | 1.52 | 0.62 | 0.05 | 0.03 | 37.82 | 17.92 | 29.37 |

| 9 | 10 | 1.62 | 50.39 | 1.47 | 0.84 | 0.07 | 0.03 | 45.57 | 23.36 | 27.77 |

| 10 | 11 | 1.66 | 51.63 | 1.62 | 0.72 | 0.06 | 0.03 | 45.53 | 19.65 | 27.51 |

| 11 | 12 | 1.49 | 46.34 | 1.41 | 0.80 | 0.07 | 0.03 | 40.54 | 19.48 | 27.63 |

| 12 | 13 | 1.54 | 47.90 | 1.50 | 0.69 | 0.06 | 0.03 | 46.14 | 19.54 | 26.73 |

| 13 | 14 | 1.82 | 56.61 | 1.73 | 1.63 | 0.11 | 0.04 | 77.87 | 4.76 | 27.73 |

| 14 | 15 | 1.54 | 47.90 | 1.49 | 0.87 | 0.07 | 0.05 | 43.30 | 22.52 | 28.26 |

| 15 | 16 | 1.52 | 47.28 | 1.34 | 0.91 | 0.08 | 0.06 | 42.35 | 20.90 | 28.79 |

| 16 | 17 | 1.86 | 57.85 | 1.52 | 1.58 | 0.10 | 0.06 | 56.24 | 3.84 | 29.47 |

| 17 | 18 | 1.25 | 38.88 | 1.47 | 0.56 | 0.10 | 0.13 | 28.63 | 18.23 | 27.72 |

| 18 | 19 | 1.39 | 43.23 | 1.67 | 0.62 | 0.11 | 0.12 | 32.01 | 19.68 | 28.66 |

| 19 | 20 | 1.50 | 46.66 | 2.03 | 0.57 | 0.16 | 0.17 | 29.29 | 19.64 | 27.51 |

| 20 | 21 | 1.47 | 45.72 | 1.67 | 0.49 | 0.17 | 0.27 | 26.70 | 15.93 | 27.84 |

| 21 | 22 | 1.43 | 44.48 | 1.70 | 0.50 | 0.14 | 0.19 | 26.99 | 17.57 | 29.00 |

| 22 | 23 | 1.39 | 43.23 | 1.71 | 0.48 | 0.16 | 0.24 | 28.10 | 17.08 | 26.79 |

| 23 | 24 | 1.49 | 46.34 | 1.64 | 0.36 | 0.24 | 0.53 | 27.32 | 15.22 | 25.54 |

| 24 | 25 | 2.00 | 62.21 | 1.58 | 0.41 | 0.25 | 0.57 | 27.48 | 16.00 | 26.63 |

| Mean | 1.53 | 47.58 | 1.47 | 0.72 | 0.09 | 0.12 | 40.67 | 18.14 | 28.12 | |

Table 10. Assay results, Drillhole SPT31

| Drillhole: SPT31 | ||||||||||

| From | To | Ag (oz/t) | Ag (g/t) | % Zn | % Pb | % Cu | Au (g/t) | Ga (g/t) | In (g/t) | % Fe |

| 0 | 1 | 1.24 | 38.57 | 0.93 | 0.77 | 0.03 | 0.03 | 79.89 | 3.24 | 24.82 |

| 1 | 2 | 1.77 | 55.05 | 0.57 | 1.44 | 0.05 | 0.05 | 98.55 | 4.12 | 24.01 |

| 2 | 3 | 1.77 | 55.05 | 0.98 | 1.43 | 0.05 | 0.05 | 109.00 | 2.32 | 25.95 |

| 3 | 4 | 1.57 | 48.83 | 0.87 | 0.64 | 0.04 | 0.02 | 71.15 | 24.56 | 28.06 |

| 4 | 5 | 1.28 | 39.81 | 0.76 | 0.45 | 0.03 | 0.03 | 51.87 | 20.87 | 28.66 |

| 5 | 6 | 1.13 | 35.15 | 0.78 | 0.56 | 0.03 | 0.03 | 56.36 | 20.84 | 27.31 |

| 6 | 7 | 1.65 | 51.32 | 1.46 | 0.76 | 0.06 | 0.03 | 55.99 | 23.32 | 27.02 |

| 7 | 8 | 1.73 | 53.81 | 1.19 | 0.69 | 0.06 | 0.03 | 53.85 | 20.50 | 29.55 |

| 8 | 9 | 1.58 | 49.14 | 1.31 | 0.83 | 0.07 | 0.03 | 71.69 | 21.88 | 24.94 |

| 9 | 10 | 1.71 | 53.19 | 1.24 | 0.63 | 0.06 | 0.03 | 55.70 | 20.66 | 27.78 |

| 10 | 11 | 1.62 | 50.39 | 1.36 | 0.78 | 0.06 | 0.03 | 56.32 | 21.21 | 26.70 |

| 11 | 12 | 1.69 | 52.56 | 1.27 | 0.58 | 0.05 | 0.04 | 33.24 | 14.69 | 33.54 |

| 12 | 13 | 1.63 | 50.70 | 1.71 | 1.87 | 0.09 | 0.05 | 97.69 | 21.48 | 26.70 |

| 13 | 14 | 1.71 | 53.19 | 1.74 | 1.81 | 0.10 | 0.05 | 77.74 | 19.56 | 26.46 |

| 14 | 15 | 1.74 | 54.12 | 1.86 | 2.16 | 0.11 | 0.06 | 112.00 | 28.08 | 26.50 |

| 15 | 16 | 1.43 | 44.48 | 1.59 | 0.77 | 0.08 | 0.08 | 31.16 | 19.31 | 28.69 |

| 16 | 17 | 1.49 | 46.34 | 1.70 | 1.21 | 0.13 | 0.08 | 61.19 | 22.72 | 27.82 |

| 17 | 18 | 1.23 | 38.26 | 1.30 | 0.72 | 0.10 | 0.09 | 55.23 | 21.53 | 27.04 |

| 18 | 19 | 1.12 | 34.84 | 1.06 | 0.58 | 0.08 | 0.11 | 32.34 | 19.14 | 26.61 |

| 19 | 20 | 1.40 | 43.54 | 1.50 | 0.82 | 0.08 | 0.07 | 37.21 | 22.13 | 27.90 |

| 20 | 21 | 1.47 | 45.72 | 1.66 | 0.82 | 0.12 | 0.07 | 39.06 | 24.32 | 29.15 |

| 21 | 22 | 1.41 | 43.86 | 1.51 | 0.74 | 0.10 | 0.08 | 43.96 | 22.03 | 28.68 |

| 22 | 23 | 1.41 | 43.86 | 1.62 | 0.70 | 0.13 | 0.10 | 34.82 | 23.14 | 27.12 |

| Mean | 1.51 | 47.03 | 1.30 | 0.95 | 0.07 | 0.05 | 61.57 | 19.20 | 27.44 | |

Drill Program

CDPR engaged Ingetrol Comercial S.A.C., a subsidiary of Grupo Ingetrol (Chile), and ConeTec Peru, a subsidiary of the ConeTec Group (Canada). The campaign utilizes percussion and sonic drilling techniques to ensure the most accurate results.

On October 23rd, the Company completed the last of 40 drillholes, ahead of the rainy season, collecting more than 1,000 samples over a significant portion of the Quiulacocha tailings deposit. The samples were safely transported to the laboratory in freezer containers and are currently under analysis.

Laboratory Testing

All samples are stored and transported to Lima in freezer containers to prevent oxidation and preserve sample integrity.

The samples are dried and tested at the Inspectorate Services Lab (Bureau Veritas) in Lima. Following geochemical and mineralogical testing, representative composites from select samples will be sent to Bureau Veritas Antofagasta (Chile) for advanced metallurgical test work program.

This extensive laboratory program will determine the mineral resource estimate and evaluate potential metallurgical methods for metal and pyrite recovery of the Quiulacocha tailings.

Quality Assurance (QA) and Quality Control (QC)

The preparation of samples for Geochemical Analyses comprises drying at 100°C and riffle splitting to obtain a representative pulp sample of 250 grams. The sample does not undergo sieving or any other mechanical preparation (crushing or grinding) to preserve the original grain size distribution.

Bureau Veritas performs all sample preparation and analytical programs, supported by the QA/QC program, which is monitored on a sample lot basis. The CDPR QA/QC program consists of inserting twin samples, coarse duplicate samples, pulp duplicate samples, standard reference materials, and coarse blank material and further checking at a second laboratory.

Geophysics

CDPR has successfully completed Phase 1 of its geophysical studies, focusing on the dry areas of the Quiulacocha Tailings. Depth readings, conducted by Geomain Ingenieros S.A.C., ranged from 20 to over 40 meters in various locations.

The Quiulacocha Tailings

CDPR is the titleholder of the concession “El Metalurgista” in Peru, which grants it the right to explore and exploit the Quiulacocha Tailings within its assigned area. The General Mining Bureau of the Peruvian Ministry of Energy and Mines has formally confirmed the enforceability of these rights.

The Quiulacocha Tailings Storage Facility covers approximately 115 hectares and is estimated to hold approximately 75 million tonnes of material processed from the 1920s to 1990s.

Initially, these tailings resulted from the mining of 16+ million tonnes of copper-silver-gold mineralization with reported historical grades of up to 10% Cu, 4 g/t Au, and over 300 g/t Ag, and later from the mining of 58+ million tonnes of zinc-lead-silver mineralized material with average historical grades of 7.41% Zn, 2.77% Pb, and 90.33 g/t Ag.

With minimal mining costs due to surface-level material and current reprocessing capacity at adjacent plants, CDPR's Quiulacocha Project stands out as one of Peru's key mining initiatives. This project provides economic benefits and aims to restore the environment and create employment opportunities, aligning with the local community's needs.

Technical Information

Mr. Alfonso Palacio Castilla, MIMMM/Chartered Engineer (CEng) and Project Superintendent for CDPR, has reviewed and approved the scientific and technical information contained in this news release. Mr. Palacio is a Qualified Person for the purposes of reporting in compliance with NI 43-101.

Cerro de Pasco Resources

Cerro de Pasco Resources Inc. is focused on the development of its principal 100% owned asset, the El Metalurgista mining concession, comprising silver-rich mineral tailings and stockpiles extracted over a century of operation from the Cerro de Pasco open pit mine in Central Peru. The company’s approach at El Metalurgista entails the reprocessing and environmental remediation of mining waste and the creation of numerous opportunities in a circular economy. The asset is one of the world’s largest above-ground resources.

Forward-Looking Statements and Disclaimer

Certain information contained herein may constitute “forward-looking information” under Canadian securities legislation. Generally, forward-looking information can be identified using forward-looking terminology such as “plans”, “seeks”, “expects”, “estimates”, “intends”, “anticipates”, “believes”, “could”, “might”, “likely” or variations of such words, or statements that certain actions, events or results “may”, “will”, “could”, “would”, “might”, “will be taken”, “occur”, “be achieved” or other similar expressions.

Forward-looking statements, including the expectations of CDPR’s management regarding the realization, timing and scope of its drilling program, the completion of a resource report as well as the business and the expansion and growth of CDPR’s operations, are based on CDPR’s estimates and are subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance or achievements of CDPR to be materially different from those expressed or implied by such forward-looking statements or forward-looking information.

Forward-looking statements are subject to business and economic factors and uncertainties and other factors, that could cause actual results to differ materially from these forward-looking statements, including the relevant assumptions and risks factors set out in CDPR’s public documents, available on SEDAR+ at www.sedarplus.ca. There can be no assurance that such statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Although CDPR believes that the assumptions and factors used in preparing the forward-looking statements are reasonable, undue reliance should not be placed on these statements and forward-looking information. Except where required by applicable law, CDPR disclaims any intention or obligation to update or revise any forward-looking statement, whether as a result of new information, future events or otherwise.

Further Information

Guy Goulet, CEO

Telephone: +1-579-476-7000

Mobile: +1-514-294-7000

ggoulet@pascoresources.com

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/82f4d6ff-6c1a-40db-b0f6-f6d074cea175

https://www.globenewswire.com/NewsRoom/AttachmentNg/19333751-0f88-4208-9a4d-3743441b1d9f