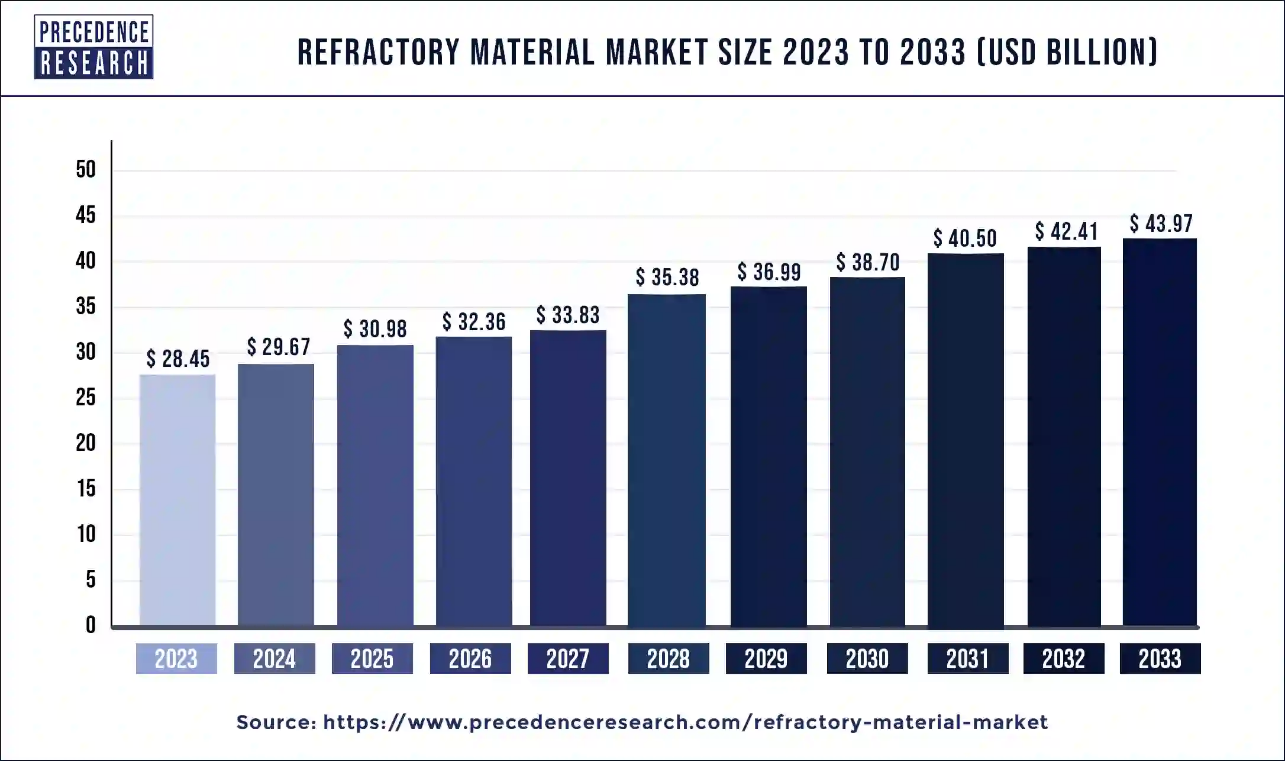

Ottawa, July 01, 2024 (GLOBE NEWSWIRE) -- According to Precedence Research, the global refractory material market size is estimated to grow from USD 28.45 billion in 2023 to USD 43.97 billion by 2033. The refractory material market is driven by the increasing use of materials in construction and evolving novel technologies.

The refractory material market encompasses the global industry involved in the production, distribution, and consumption of material designed to withstand high temperatures, mechanical wear, and chemical corrosion. Various industries employ refractory materials such as silica bricks, magnesium refractories, zirconia refractories, fireclay refractories, chromite refractories, and monolithic refractories. Silica bricks have excellent mechanical strength and are utilized in the glass and steel industries.

Fireclay refractories are widely used and affordable, but magnesium refractories are chemically essential and resistant to basic slags. High alumina refractories contain more than 45% alumina and are used in lime and ceramic kilns, furnaces, cement kilns, crucibles, and glass tanks for melting metals. Zirconia refractories offer exceptional harnesses at room temperature and are suited for use in high-temperature building materials.

The Full Study is Readily Available | Download the Sample Pages of this Report@ https://www.precedenceresearch.com/sample/2122

Refractory Material Market Revenue (US$ Million), By Chemistry, 2020 - 2023

| Chemistry | 2020 | 2021 | 2022 | 2023 |

| Acidic | 12,165.27 | 12,702.23 | 13,333.38 | 13,918.64 |

| Basic | 10,149.98 | 10,632.95 | 10,542.73 | 11,057.04 |

| Neutral | 3,284.95 | 3,368.39 | 3,388.23 | 3,474.67 |

Refractory Material Market Revenue (US$ Million), By Chemical Composition, 2020 – 2023

| Chemical Composition | 2020 | 2021 | 2022 | 2023 |

| Alumina | 2,447.07 | 2,557.32 | 2,609.71 | 2,724.24 |

| Silica | 4,284.43 | 4,508.78 | 4,636.52 | 4,879.67 |

| Magnesia | 2,075.56 | 2,199.49 | 2,279.77 | 2,415.81 |

| Fireclay | 16,259.59 | 16,899.46 | 17,191.40 | 17,874.97 |

| Others | 533.55 | 538.52 | 546.94 | 555.65 |

Refractory Material Market Revenue (US$ Million), By End Use, 2020 - 2023

| End Use | 2020 | 2021 | 2022 | 2023 |

| Metals & Metallurgy | 17,414.99 | 18,098.23 | 18,409.80 | 19,138.31 |

| Cement | 1,880.53 | 1,971.07 | 2,013.88 | 2,106.43 |

| Glass & Ceramics | 3,145.48 | 3,335.89 | 3,461.24 | 3,670.57 |

| Power Generation | 2,357.05 | 2,480.28 | 2,554.56 | 2,688.83 |

| Others | 802.14 | 818.10 | 824.86 | 846.19 |

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/2122

Refractory Material Market Key Insights

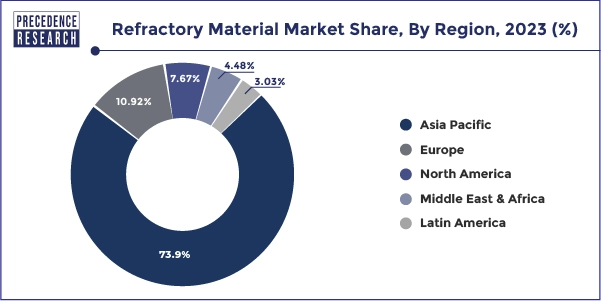

- Asia-Pacific has held the largest revenue share of 73.9% in 2023

- By chemical composition, the fireclay segment has contributed more than 62.82% of revenue share in 2023.

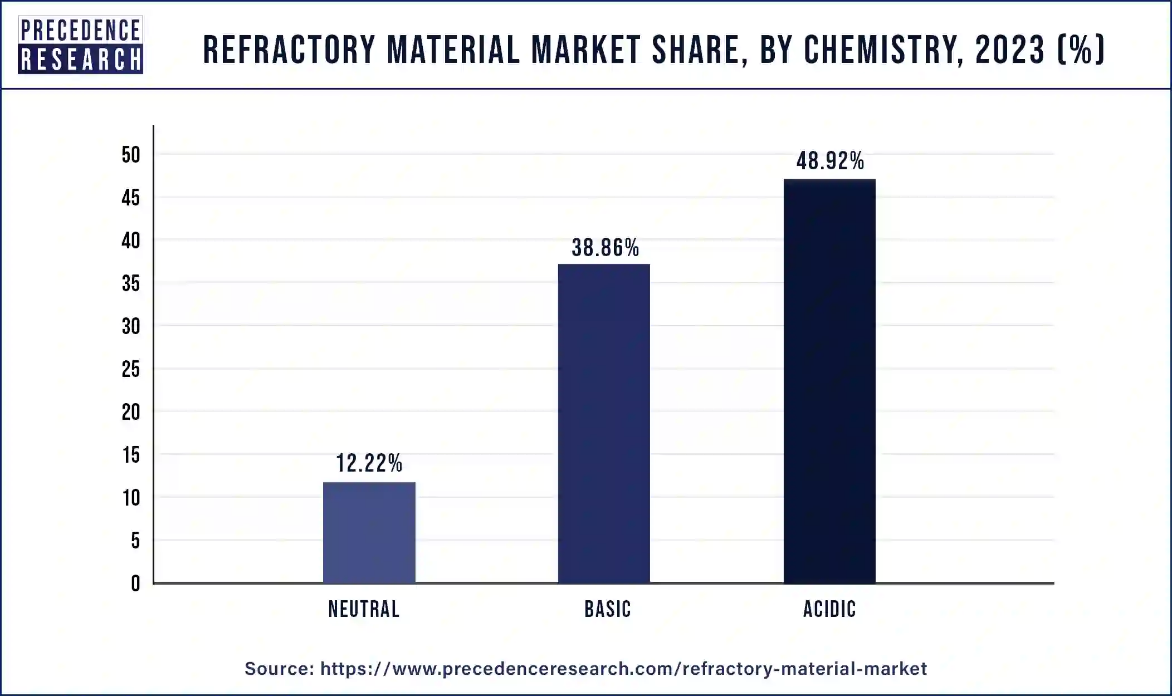

- By chemistry, the acidic segment has recorded the highest revenue share of 48.92% in 2023.

- By form, the shaped segment has generated the largest revenue share of 65.94% in 2023.

- By end use, the metals & metallurgy segment captured 67.26 % market share in 2023.

Refractory Material Market Projections for Growth by Region Shows:

- North America refractory material market size was estimated at USD 2.18 billion in 2023 and is growing at a CAGR of 3.95% from 2024 to 2033, to reach around USD 3.21 billion by 2033.

- Europe refractory material market size is anticipated to reach around USD 4.45 billion by 2033 from USD 3.10 billion in 2023 and is expanding at a CAGR of 3.66% between 2024 to 2033.

- MEA refractory material market size accounted for USD 1.27 billion in 2023 and is expected to hit around USD 1.54 billion by 2033 to grow at a CAGR of 1.94% from 2024 to 2033.

Asia Pacific Refractory Material Market Size and Forecast

The Asia Pacific refractory material market size reached USD 21.02 billion in 2023 and is predicted to be worth around USD 33.07 billion by 2033, growing at a CAGR of 4.63% from 2024 to 2033.

Asia-Pacific dominated the refractory material market in 2023. The growing market for nonmetallic minerals and materials, together with rising demand for refractories from the steel and iron sectors, is propelling the heavy machinery manufacturing sector forward. However, environmental concerns and an increase in automotive demand are limiting growth, creating an opportunity for additional expansion.

- For instance, The municipal council of Kraljevo, Serbia, announced the opening of a 10.8 million euro ($11.8 million) refractory materials facility by Punai, a Chinese company that is a subsidiary of Puyang Refractories Group (PRCO). The general director of Punai Serbia, Fan Jun Ling, was cited in a news release on Monday as claiming that the facility would be able to manufacture 20,000 tonnes of unshaped goods and 50,000 tonnes of magnesium carbon bricks yearly once it achieves its full production capability. Over thirty people will be employed by the factory. Punai started rehabilitation work there in 2022. It is situated on the site of a factory owned by the bankrupt Serbian company Magnohrom, which produces fire-resistant materials. The largest refractory maker in China, PRCO Group employs over 5,000 people in fifteen abroad offices.

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

Refractory Material Market Coverage

| Report Attribute | Key Statistics |

| Market Size in 2033 | USD 43.97 Billion |

| Market Size in 2024 | USD 29.67 Billion |

| Growth Rate From 2024 to 2033 | CAGR of 4.45% |

| Base Year | 2023 |

| Historical Year | 2021-2022 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | Chemistry, Chemical Composition, Form, End Use and Region |

| Regional Scope | North America, APAC, Europe, Latin America, MEAN, Rest of the World |

Refractory Material Market Report Highlights

Chemical Composition Outlook

The fireclay segment dominated the refractory material market in 2023. Fireclay is a refractory material that is commonly used in the building sector owing to its remarkable characteristics and ability to tolerate high temperatures without affecting structural integrity. It is generally made up of natural elements like kaolinite group clays, quartz, micas, sulfur compounds, and organic matter.

Fire clay’s fusion point exceeds 1600°C, making it ideal for kilns, lining furnaces, and other high-temperature applications. It has low thermal conductivity, strong compressive strength, minimal shrinkage at high temperatures, heat resistance, and excellent insulating quantities. Fire clay is used to make fire-resistant materials, refractory bricks, and ceramics, which keep furnaces safe and efficient by insulating heat and adding to energy efficiency. Its advantages include flexibility, chemical stability, exceptional fire resistance, and longevity.

Customize this study as per your requirement@ https://www.precedenceresearch.com/customization/2122

Chemistry Outlook

The acidic segment dominated the refractory material market in 2023. Acidic refractory is a material that contains more than 93% SiO2, is resistant to acid slag erosion at high temperatures, and is likely to react with alkaline slag. It is mostly composed of quartz glass, fused silica, silica bricks, and amorphous silicon. It is utilized in a variety of applications, including coke ovens, open hearth regenerators, furnace tops, acid furnaces, refractory kilns, and glass kilns, but is not resistant to alkaline slag or flux.

Form Outlook

The shaped segment dominated the refractory material market. Refractory shapes are prefabricated forms built of refractory materials for use in high-temperature applications such as kilns, furnaces, and incinerators. They are created under regulated conditions, assuring constant quality and performance. They minimize installation time, resulting in higher production and less downtime. Precast refractory forms are engineered to fulfill certain performance specifications, such as chemical resistance, high-temperature resistance, and thermal shock resistance, resulting in higher performance and longer service life. They are widely utilized in sectors such as aluminum, cement, steel, and glass furnaces and incinerators, kilns, the petrochemical industry, and power generation.

Shaped forms enable simplicity of installation and decreased maintenance times, with unique purpose-developed materials, consistent manufacturing process, low contact with production, simpler slag removal, optimized areas of higher wear, and faster installation and heat-up times.

End Use Outlook

The metals & metallurgy segment dominated the refractory material market. Refractory materials are important in the metallurgical industry because they can tolerate high temperatures, severe environments, and chemical reactions. They are utilized for furnace linings, insulation, chemical resistance, and thermal shock resistance.

Furnace linings shield furnace walls from extreme temperatures and corrosive conditions during metal melting and processing. Insulators keep the proper temperature, while chemical resistance prevents contamination and extends furnace life.

Browse More Insights:

- Alumina Market Size and Forecast: The global alumina market size was exhibited at USD 41 billion in 2022 and is anticipated to reach around USD 64.59 billion by the end of 2032 with a registered CAGR of 4.7% during the forecast period 2023 to 2032.

- Chromium Market Size and Forecast: The global chromium market size was exhibited at USD 22.66 billion in 2023 and is projected to hit around USD 36.69 billion by 2032, expanding at a CAGR of 5.50% from 2023 to 2032.

- Silicon Tetrachloride Market Size and Forecast: The global silicon tetrachloride market size was valued at USD 2.40 billion in 2022 and is expected to hit USD 3.40 billion by 2032, exhibiting growth at a CAGR of 3.60% during the forecast period 2023 to 2032.

- Insulation Materials Market Size and Forecast: The global insulation materials market size was estimated at USD 67 billion in 2022 and it is projected to surpass around USD 110.7 billion by 2032, growing at a CAGR of 5.20% during the forecast period 2023 to 2032.

- Insulation Market Size and Forecast: The global insulation market size was estimated at USD 58.94 billion in 2023 and is projected to hit around USD 117.07 billion by 2033, poised to grow at a compound annual growth rate (CAGR) of 7.10% during the forecast period from 2024 to 2033.

- Hydropower Generation Market Size and Forecast: The global hydropower generation market size was estimated at US$ 222 billion in 2022 and it is expected to hit over US$ 380.99 billion by 2032 with a registered CAGR of 5.60% from 2023 to 2032.

- Coal Power Generation Market Size and Forecast: The global coal power generation market demand was estimated at 2,060.44 giga watts in 2022 and is expected to hit around 2,806.93 giga watts by 2032, poised to grow at a CAGR of 3.14% during the forecast period from 2023 to 2032.

- Metal Recycling Market Size and Forecast: The global metal recycling market size was valued at USD 119.3 billion in 2022, and it is projected to hit around USD 249.4 billion by 2032, with a CAGR of 7.7% from 2023 to 2032.

- Metal Powder Market Size and Forecast: The global metal powder market was valued at USD 5.81 billion in 2023 and is predicted to surpass around USD 10.97 billion by the end of 2033, representing an impressive CAGR of 6.6% during the forecast period 2024 to 2033.

- Basic Chemicals Market Size and Forecast: The global basic chemicals market size was valued at USD 671.45 billion in 2022 and is expected to be worth around USD 979.63 billion by 2032, anticipated to grow at a CAGR of 3.9% over the forecast period from 2023 to 2032.

Refractory Material Market Dynamics

Driver: Reduced project cost and improved properties

Refractory materials are becoming more popular in the building industry because of their unique properties. They lessen the need for expensive maintenance, eliminate downtime and job site shutdowns, and save project costs. Refractory materials, such as castable refractory cement and acid-proof bricks, are designed to last for many years with little care.

They also increase the mechanical and chemical qualities of metallic materials, making them an important asset in the building industry. The refractory sector has expanded rapidly in recent years.

Restraint

When refractory cement collapses, its strength can harm the environment and individuals because interior components such as asbestos can mix with air particles, causing tissue scarring and respiratory problems like asbestosis. This can potentially lead to malignant disorders, such as mesothelioma.

Opportunity: Additives for refractory materials

The refractory material market is going through a tremendous transition as additive manufacturing (AM) gathers popularity. Cement, steel, and glass sectors all rely on refractory materials, which are recognized for their heat-resistance qualities.

Additive manufacturing provides benefits such as better design freedom, waste reduction, quicker prototyping, and the capacity to build complex shapes. This can speed up the creation of high-performance, bespoke refractory components and minimize lead times. Opportunities include modifying components to fit specific client needs, minimizing maintenance downtime, and mastering complicated geometries. This revolutionary manufacturing technology transforms refractory material designs, increasing efficiency and effectiveness.

Refractory Material Market Leaders

- Calderys

- IFGL Refractories Ltd.

- SHINAGAWA REFRACTORIES CO., LTD.

- Dalmia Bharat Refractory

- RHI Magnesita GmbH

- Vitcas

- Morgan Advanced Materials

- Saint Gobain

- Krosaki Harima Corporation

- Lanexis

Recent Developments

- In January 2023, The Korea Institute of Science and Technology (KIST) developed a thermally refractory material alongside optical properties up to 1000 degrees Celsius and strong ultraviolet light. It is suitable for space, aerospace, and thermal photovoltaic systems, which use thermal radiation for cooling, heating, and energy production.

- In February 2023, Calderys and HWI created the Calderys Group, which is a prominent provider of high-temperature solutions. The new group employs technology from all locations to provide a broader array of world-class refractory materials for the high-temperature sector globally. It has launched an ambitious technology exchange initiative, moving Calderys solutions from the Americas to HWI and acquiring HWI goods in EMEA and APAC.

- In October 2023, RHI Magnesita bought the Preiss-Daimler Group's refractory operations in Germany, the Czech Republic, and Slovenia for €45 million. P-D Refractories, a prominent manufacturer of alumina-based refractories for industrial purposes, has refractory operations in Germany and the Czech Republic, as well as clay, quartzite, and silica raw material sources.

- In August 2023, The European research project ReSoURCE seeks to create sustainable recycling solutions for refractory materials that can endure temperatures beyond 1,500°C. These elements are critical for industrial furnaces that manufacture glass, ceramics, nonferrous metals, and steel. With 32 million tons of refractory materials generated each year, only a portion is recycled, with German project partners supplying laser expertise.

Market Segmentation

By Chemistry

- Acidic

- Basic

- Neutral

By Chemical Composition

- Alumina

- Silica

- Magnesia

- Fireclay

- Others

By Form

- Shaped

- Unshaped

By End Use

- Metals & Metallurgy

- Cement

- Glass & Ceramics

- Power Generation

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/2122

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

Unlocking Market Insights through Data Excellence

The "Precedence Statistics" flexible dashboard is a powerful tool that offers real-time news updates, economic and market forecasts, and customizable reports. It can be configured to support a wide range of analysis styles and strategic planning needs. This tool empowers users to stay informed and make data-driven decisions in various scenarios, making it a valuable asset for businesses and professionals looking to stay ahead in today's dynamic and data-driven world.

To Access our Premium Real-Time Data Intelligence Tool, Visit: http://www.precedencestatistics.com

About Us

Precedence Research is a worldwide market research and consulting organization. We give an unmatched nature of offering to our customers present all around the globe across industry verticals. Precedence Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures present globally.

Web: https://www.precedenceresearch.com

Our Blogs:

https://www.towardshealthcare.com

https://www.towardspackaging.com

https://www.towardsautomotive.com

For Latest Update Follow Us: