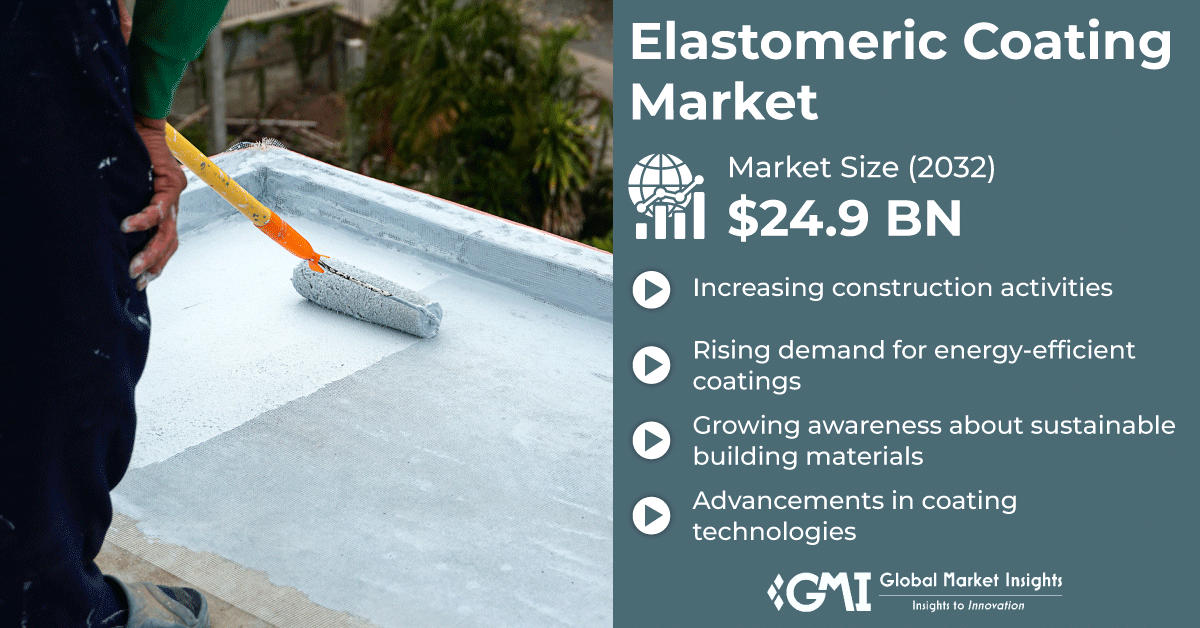

Selbyville, Delaware , Aug. 28, 2024 (GLOBE NEWSWIRE) -- Elastomeric Coating Market is projected to reach USD 24.9 billion by 2032, as per a recent study by Global Market Insights Inc.

Technological innovations in coating technologies, such as advanced formulations enhancing durability and performance, are pivotal in bolstering the industry. These innovations meet evolving demands for sustainable and high-performance solutions, stimulating the growth trajectory.

Request for a sample of this research report @ https://www.gminsights.com/request-sample/detail/8636

Referencing an instance, in April 2023, Gaco introduced GacoFlex A48, a new acrylic elastomeric roof coating. It boasts high-build capability, applying up to 80 wet mils (5 gal/SQ) in one pass, offering extended roof life, enhanced aesthetics, robust adhesion, high tensile strength, and superior reflectivity.

The elastomeric coating enhances energy efficiency, supports industrial applications, and benefits from urbanization and government initiatives promoting sustainable construction. Their superior durability and long lifespan make elastomeric coatings a preferred choice for protecting building exteriors and infrastructure, ensuring long-term performance and reliability.

Polyurethane Sector Takes the Lead

The polyurethane segment will garner a prominent elastomeric coating market share by 2032. The demand for elastomeric coatings in the polyurethane segment is rising due to their superior flexibility, durability, and weather resistance. Polyurethane elastomeric coatings offer excellent protection against harsh environmental conditions, such as UV radiation and temperature fluctuations, making them ideal for roofing and exterior applications. Additionally, their ability to expand and contract with building materials without cracking enhances their longevity and performance. The growing emphasis on energy efficiency and sustainability in construction thrusts the adoption of polyurethane-based elastomeric coatings, strengthening the growth of the elastomeric coating sector.

Leading Role of Solvent-borne Segment in the Sector

The solvent-borne segment of the elastomeric coating market will show a notable CAGR from 2024 to 2032. The solvent-borne segment among diverse elastomeric coatings is gaining popularity because of their quick drying times, superior adhesion, and better durability. These coatings provide robust protection against harsh environmental conditions, making them ideal for industrial and commercial applications. Solvent-borne elastomeric coatings are also known for their excellent penetration into porous surfaces, ensuring long-lasting performance and resistance to moisture and chemicals. Additionally, advancements in formulation technologies have reduced the VOC content in these coatings, aligning them with environmental regulations and bolstering their popularity in the market.

Make an inquiry for purchasing this report @ https://www.gminsights.com/inquiry-before-buying/8636

North America Sets the Pace in Industry

North America's elastomeric coating market proliferates primarily because of its effectiveness in extending the lifespan of buildings and infrastructure. These coatings provide superior protection against extreme weather conditions prevalent in the region, such as intense sunlight, heavy rains, and temperature fluctuations. Additionally, their ability to improve energy efficiency by enhancing insulation properties appeals to building owners and operators aiming to reduce operational costs. Stricter environmental regulations encouraging the adoption of low-VOC coatings amplify adoption. Moreover, the ongoing maintenance and renovation of existing structures also contribute to the increasing demand for elastomeric coatings in North America.

Elastomeric Coating Market Players

Major elastomeric coating manufacturers include Sika AG, The Dow Chemical Company, Arkema Group, 3M Company, BASF SE, Dulux Group Limited, Benjamin Moore & Co., PPG Industries, Inc., Gaco, Jotun Group, Nippon Paint Holdings Co., Nouryon, The Sherwin-Williams Company, Hempel A/S, Ltd., and others.

The competitive landscape is dominated by key elastomeric coating producers focusing on strategic initiatives to maintain significant market shares. The elastomeric coating producers invest heavily in research to innovate and expand product applications. Strategic collaborations between large-scale companies and emerging players are common, aiming to enhance competitiveness and drive innovation. Competitors are evaluated based on product performance, durability, and application-specific features. The elastomeric coating industry emphasizes sustainability and compliance with stringent environmental regulations, influencing product development strategies across the elastomeric coating industry.

In April 2023, Datwyler launched UltraShield, spearheading dual film and spray fluoropolymer coating technologies for injectable drug closures. This advancement improves drug stability, caters to strict quality demands, and encourages pharmaceutical usage, strengthening Datwyler's leadership in parenteral packaging solutions.

In March 2023, Pearl Polyurethane Systems introduced the cutting-edge DuraPearl Elastomer System for spray coatings. This provides superior strength over epoxy, improving productivity. Perfect for different climates, assuring durability with nominal environmental influence.

About Global Market Insights

Global Market Insights Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy, and biotechnology.